Paper honeycomb panel is a honeycomb mesh sandwiched between two plies of recycled cardboard. Due to unique structural properties, the honeycomb cardboard panels have the exceptional durability that accompanies nature-friendly packing, transporting, and storage solutions.

The use of organic and naturally occurring adhesives, used to bind different layers of honeycomb cardboard panels together, made this material reliable and sturdy. Such a manufacturing process advocates for socially and ecologically responsible practices and their promotion. As recycled materials are used in the process, the lack of any toxic substances makes honeycomb products 100% natural and safe to use in various environments and near food.

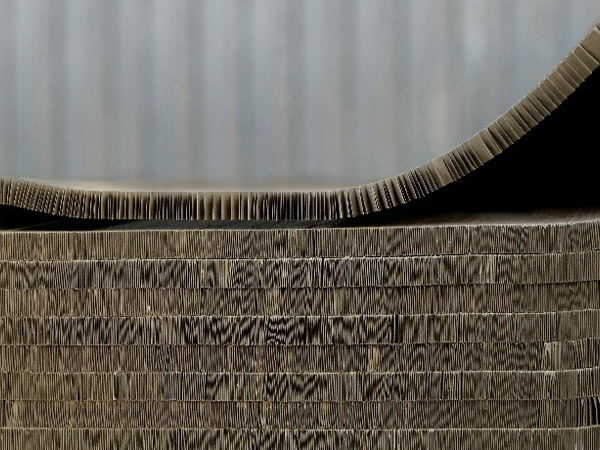

The strength properties of the honeycomb panels depend on the size of cells and grammage of the paper used to produce them – the smaller the cells are, the stronger the mesh is, allowing it to compete with the wood, corrugated cardboard, paper corners, polystyrene foam, or even steel! The bigger the grammage describes the stress and compressive resistance of the honeycomb fillers and boards. Even it may seem that the thickness of the honeycomb filler should affect its durability, this approach is more than wrong. As the thickness of the honeycomb filler can vary from 10 mm to 100 mm, it does not make the difference when withstanding loads of up to 800 kg/m2.

Despite the strength and durability, honeycomb cardboard panels are lightweight. As this material has a lightness feature, it can be used even in the aviation industry, where cargo’s weight is a very important aspect. Honeycomb cardboard is often used packing products to be transported by air as this material weighs about 10 times less than wooden boards from pressed chips. The very honeycomb technology also allows the creating lighter aircrafts than ever before. Company Hexcel is the world leader in manufacturing honeycomb plastic and aluminium sheets for the commercial aerospace market, thus, being the industry’s pioneers and extending the use of honeycomb technology into the new horizons such as sports equipment or transport.

Honeycomb cardboard fillers

Honeycomb cardboard filler provides good thermal and sound insulation making it the perfect alternative for building temporary structures – kiosks, booths, shelters, etc. Two types of inserts – simple ones and potted inserts – are mostly used in the process of mechanically attaching, securing, and fastening different honeycomb panels together or with various materials such as aluminium to create challenging structures.

Honeycomb cardboard panels are one of the most versatile materials in the world. As they can be used in many industries starting from packaging, logistics, advertising, and finishing with interior design, furniture, and door manufacturing, honeycomb cardboard panels are a great option for those who seek to buy a reliable product for a friendly price. Material’s applicability is increased, making composite and laminated honeycomb panels – sandwiching even more sturdy layers together and providing an opportunity for people to use this material in DIY processes!

Honeycomb cardboard inserts and spacers

Honeycomb inserts and spacers are the best options for smart packaging solutions as material reliability and sturdiness guarantees safely transporting of breakable and fragile items, appliances, car parts, and other products. Honeycomb cardboard panels can be cut into different sizes and shapes, making the material perfect for furniture as well. Door panels are one of the most popular things to make from honeycomb cardboard as its features meet the needs of customers.

You now know how great the honeycomb cardboard is – contact us to discuss its applicability options for your business as we have a great variety of honeycomb cardboard for sale!