The furniture sector is always on a look-out for new and innovative packaging solutions that can improve both furniture transportation and overall user experience. As sturdiness is one of the main aspects not only when choosing a new piece of furniture but also while transporting, honeycomb fillers, spacers, and panels are an alternative to polystyrene packing chips or foam. This material has long been used for the smart packaging of products and, as furniture is coming in all shapes and sizes, it is understood that such packaging will also be applied in the furniture manufacturing industry.

Honeycomb panels sturdy and resistant to compression, making it the perfect material for the boxes to pack the furniture items. As honeycomb cardboard products can withstand heavy loads of up to 800 kg/m2, the material confirms protecting the product from external damage during transportation. Despite being very strong, the cardboard honeycomb products are lightweight, allowing people to carry the packed furniture very easily. Furniture packaging made of honeycomb core panels is about 60 % lighter than other packaging solutions. This feature reduces the overall cost of products and is a great advantage in safely transporting the furniture.

Besides other benefits, the cardboard honeycomb fillers, spacers, and panels are made from recycled cardboard. Different plies of paper and honeycomb core are bonded together using natural adhesive. As the product itself is easy to recycle and turn into other objects once again, it also does not release any harmful substances which may transfer to the furniture item itself and could possibly hurt its owners. Such solutions are cheaper and lighter than their prototypes from polystyrene, thus, saving money not only on the product itself but also for shipping. Honeycomb core has amazing sound and thermal insulation properties; however, these advantages are more relevant to cardboard honeycomb furniture making rather than the transportation of finished items.

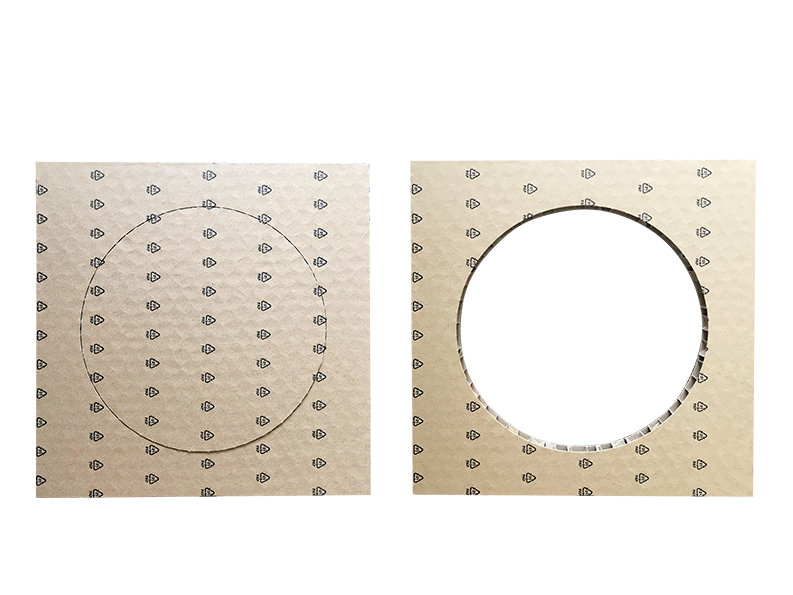

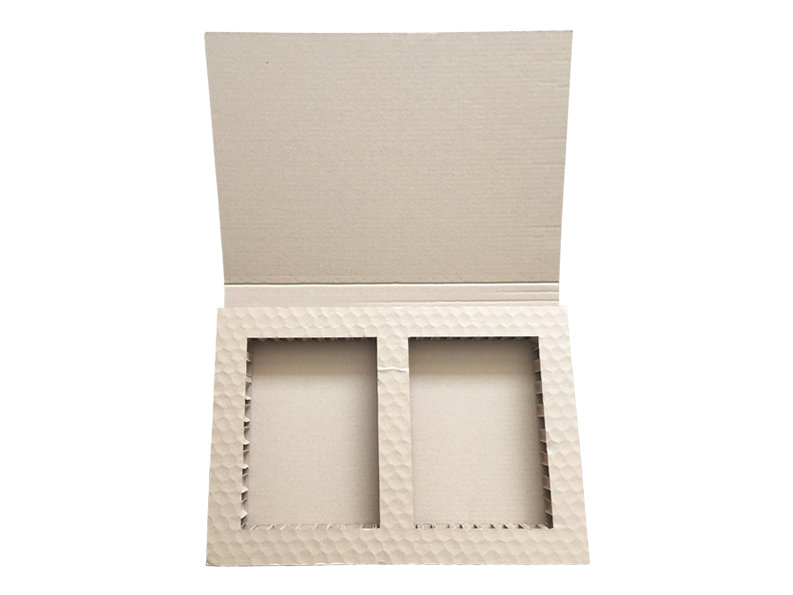

As only specific furniture items can be put in a box to fit it exactly, cardboard honeycomb fillers and spacers are used inside furniture packaging to prevent the products from moving and deforming during the transportation process. Honeycomb is very versatile; it can be cut and mend not only to create simple boxes but for executing far more difficult furniture packaging designs.

For intricate furniture fitting details, individual format honeycomb cardboard panels can be used allowing for the selection of appropriate cardboard strength according to the customer’s price-demand ration. For even safer transportation, cardboard overlays can be used and made to fit the outside of the pallet and on the inside of the cargo trucks. Our experts are ready to advise you on how to pack furniture ordering both large and small editions of eco-packaging solutions. Packaging samples can be produced if necessary.