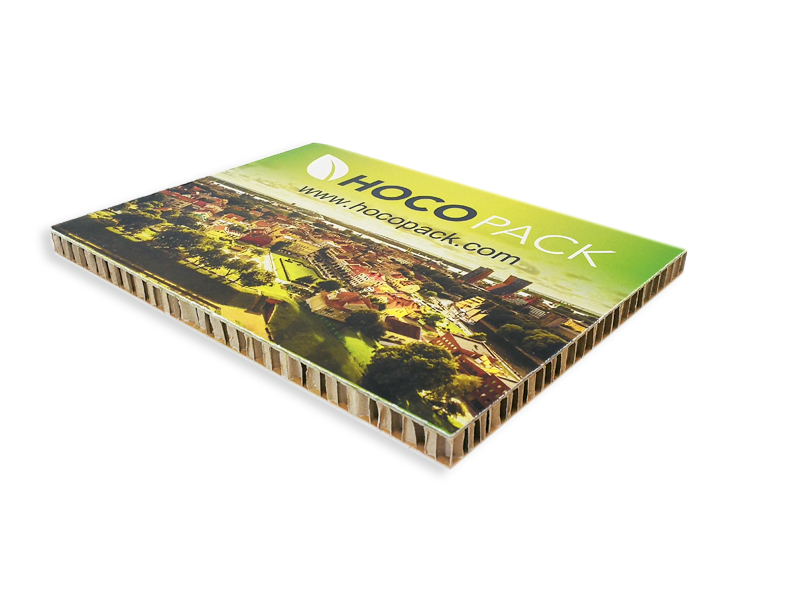

The first impression is very important to the future of one’s business, so various advertising solutions come in handy. Honeycomb cardboard and panels are used to make showcase decorations, promotional stands and panels, display shelves, and special equipment for exhibitions. Simple and more intricate design solutions are adapted to make portable yet sturdy cardboard creations that can be used for greeting cards, like the magazine, newspaper, book, flyer, baby basket, or high tea stands, etc.

Eco-friendly corrugated and honeycomb cardboard is perfect for making eye-catching exhibition ideas reality. Suppliers are ready to design cut colorful banner or a backdrop for your floor stand with plenty of storage space. We also have simple design pre-made cardboard stands and shelves for sale.

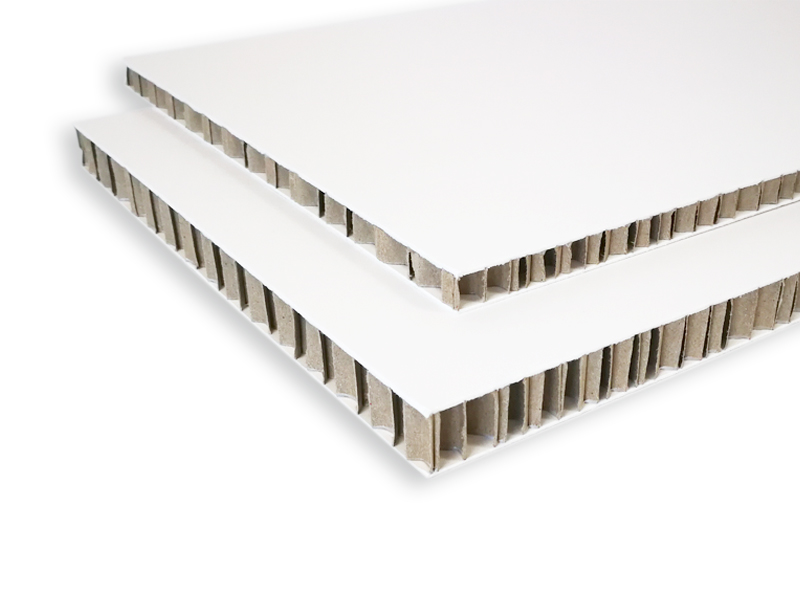

The honeycomb panel is produced specifically for advertising solutions and is suitable for UV printing. Honeycomb panels are made by gluing honeycomb core between two layers of thick white paper. Only natural glue that contains no toxic materials is used for production. These boards are known for their extreme durability, good thermal and sound insulation. Thanks to their properties, the design of the honeycomb panels makes them highly useful for advertising solutions, while the options for implementing various creative solutions are endless. Honeycomb panels can be used in a variety of areas: visual advertising and cardboard furniture production, display stands, equipment for exhibitions, interior design, creating artwork, toys for children.

Technical specifications of honeycomb panels

- Ideal for digital (UV) printing

- Lightweight, compact and ergonomic

- Easy to assemble without the need to use additional tools

- Easily customisable for various fields

- Strong and stable

- More durable and lighter than fibreboards

- These are recycled paper products that are eco-friendly and 100% recyclable.

Panel processing, production of shaped boards

Our modern CNC cutting units make it possible to achieve precise accuracy when cutting out shaped boards. With easy-to-change modules, we can achieve various shapes and cuts, cut materials of various types and thicknesses, crease, bend, puncture, and perform all other necessary panel processing works.